Intro

I needed a temperature-controlled environment for a project I'm working on. Such things exist, but I didn't want to pay an arm and a leg, so I set out to build one myself.

Components

If you look around on ebay, you can find all manner of peltier cooling modules. These come complete with hot/cold blocks and fans. Perfect!

Also on the 'bay are these neat digital thermostat modules called W1209. You set the desired temperature on the module, it has a little temperature sensor on a wire, and it uses that to click a relay on or off. Dead simple, perfect for this project.

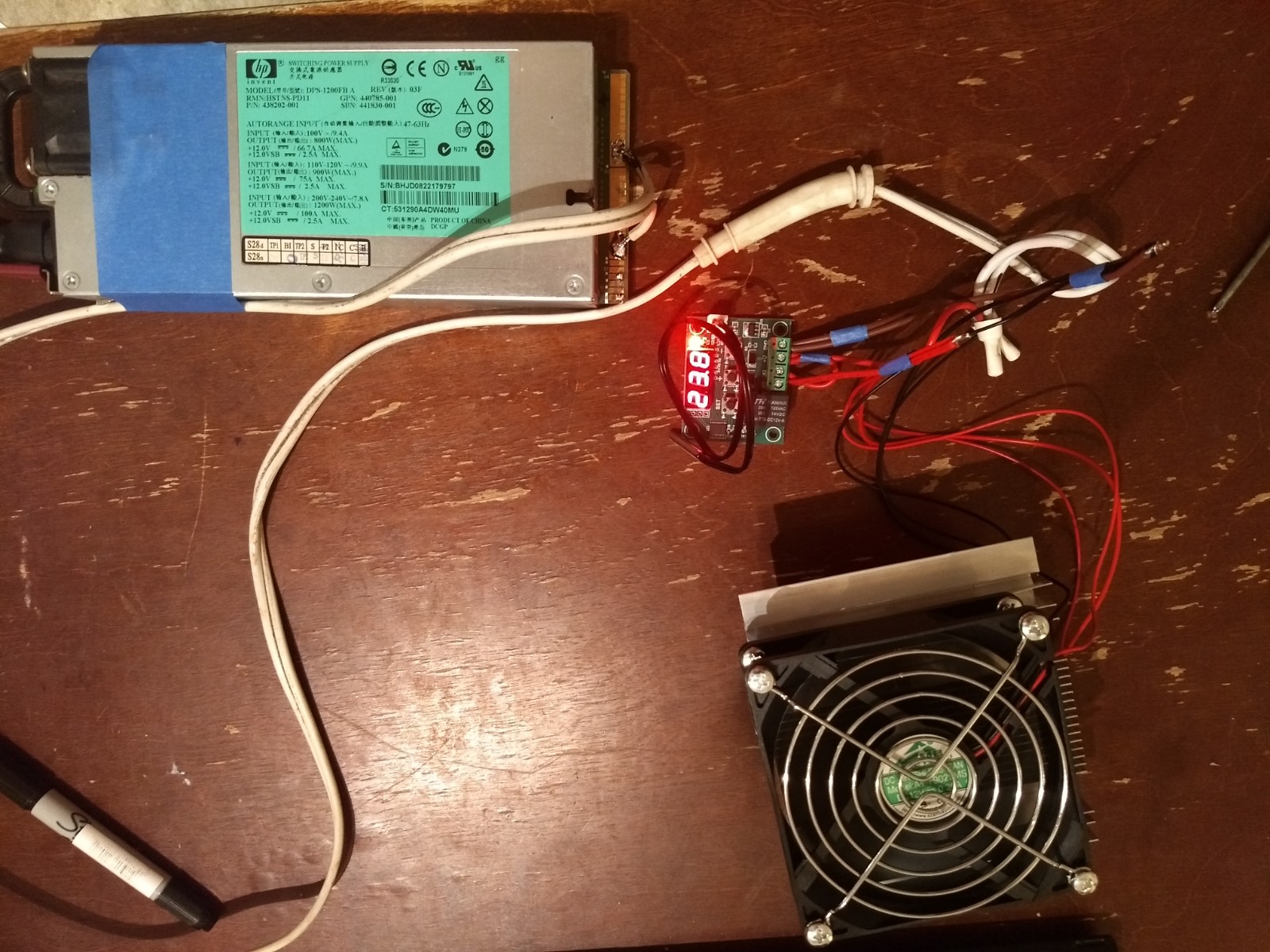

The peltier module and W1209 both run on 12V. To supply it, I used an old HP server PSU. Model# DPS-1200FB. These provide amps and amps of 12V, and will do it all day. You can find them pretty cheap because they were popular for powering GPUs during the crypto boom.

For the cooling chamber, I got one of those inexpensive styrofoam coolers you find at the grocery store. Lifoam pretty much has the market cornered on these, and that's what I used.

Construction

I started by hacking a resistor onto the PSU in order to turn it on. According to this reference, the PSU wants a value between 300 and 1k ohms on pins 33 and 36 in order to turn on. I used a 550 ohm resistor (an 0805 soldered tombstone style, with a bridge wire), and the PSU liked that just fine.

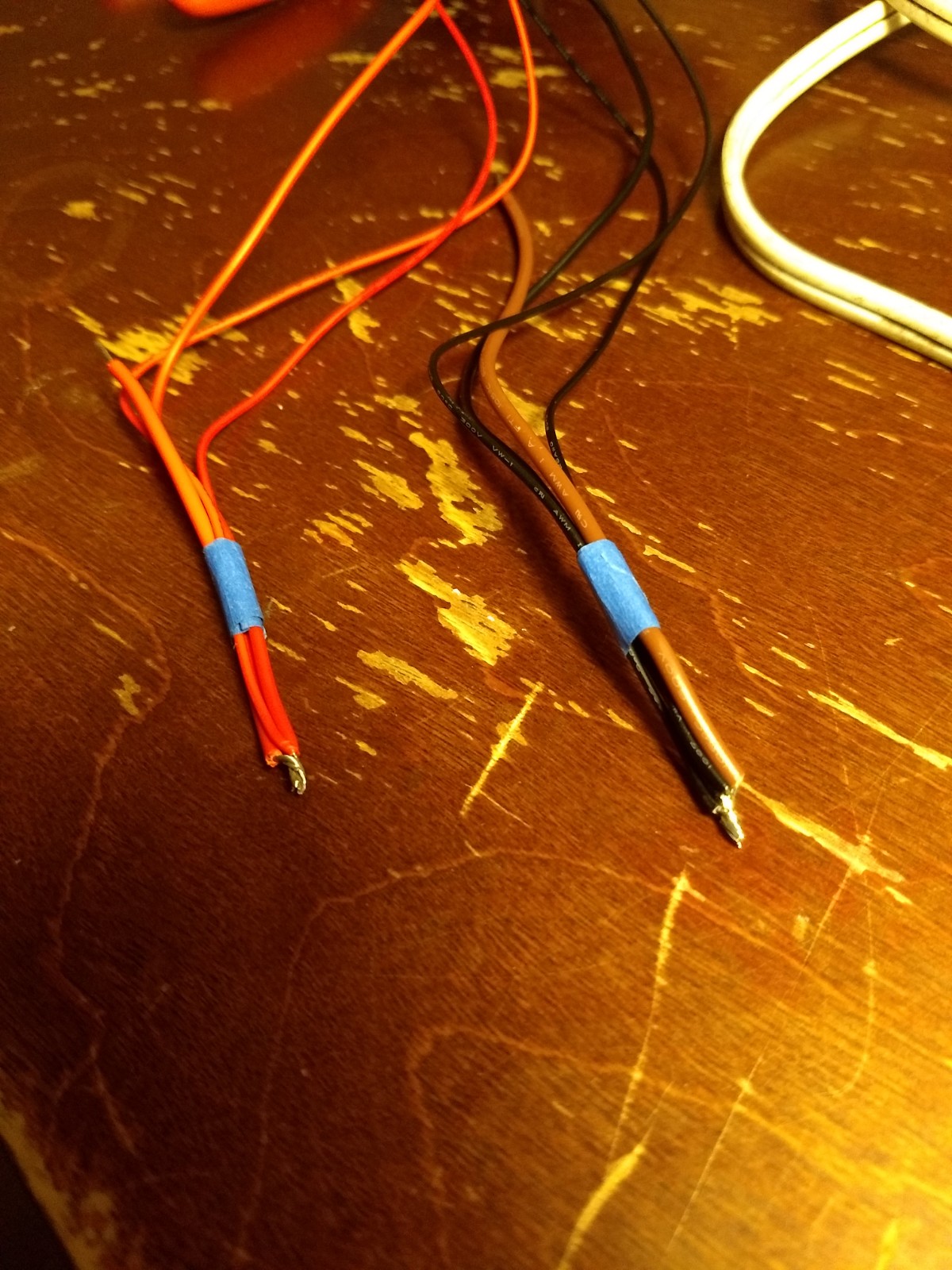

Next, I cleaned up the wiry mess of the peltier module. I bundled all the red wires together and all the black wires together, and soldered a single lead to each. This simplifies the wiring, because otherwise you're going to have a bad time fitting them all into the terminal blocks on the W1209. Remember to strain relieve your connections.

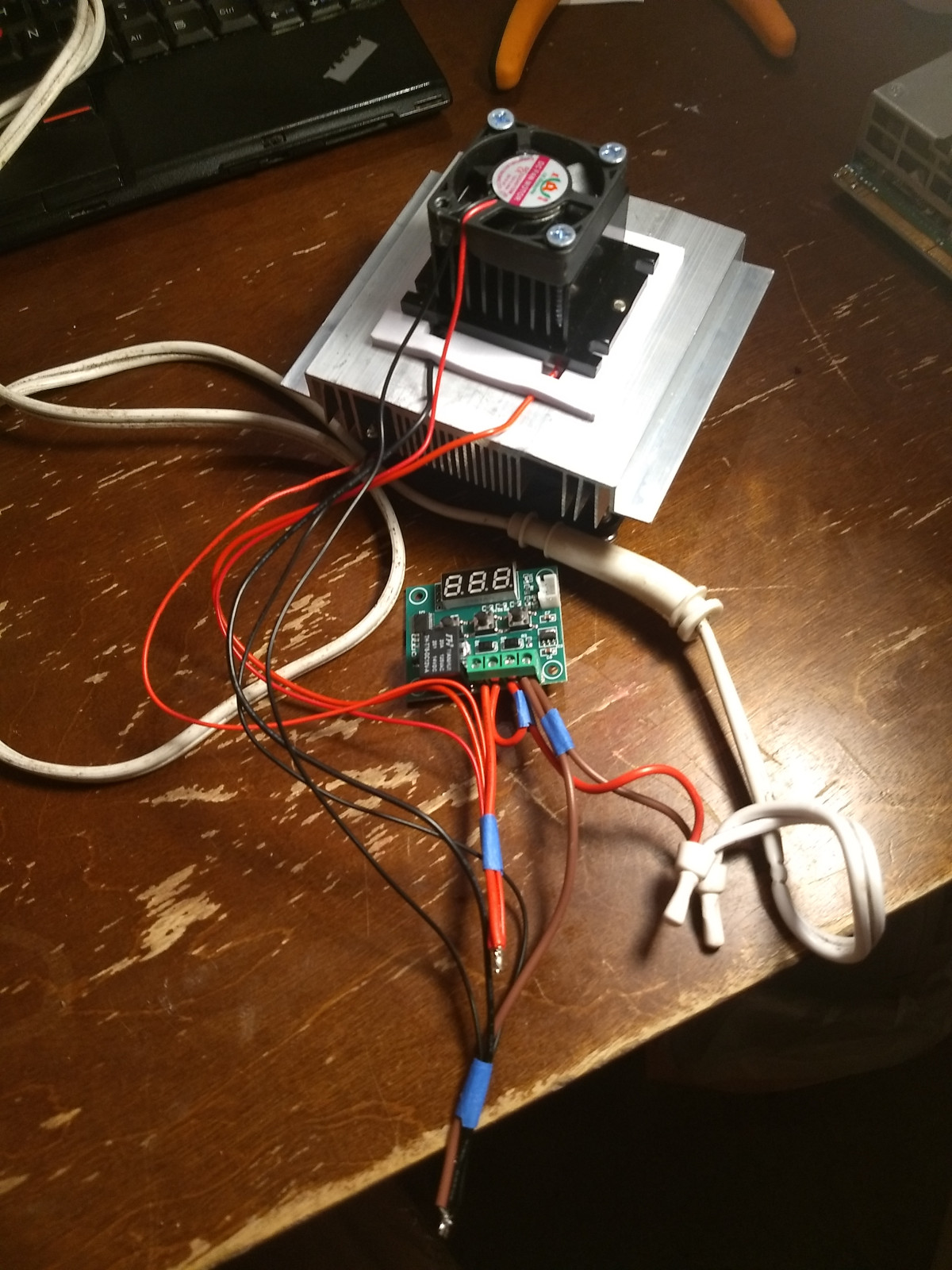

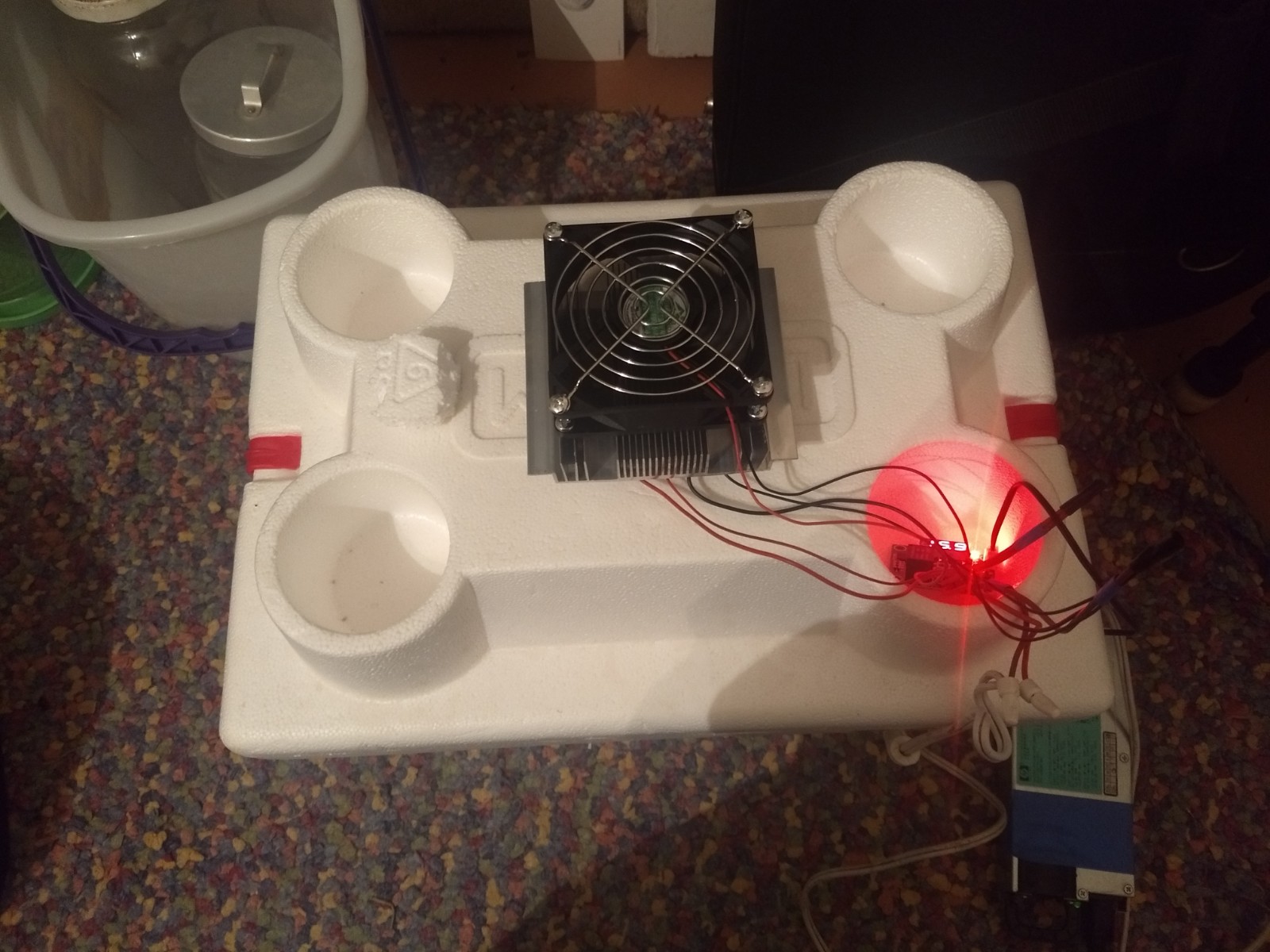

Here's a picture showing how everything is wired. The white, 2-conductor wire carries 12V and GND from the PSU. The 12V goes into the W1209's +V terminal and its K1 terminal. The red wires from the big fan, small fan, and peltier module are connected together with a common lead. This goes into the K0 position on the W1209. The black wires from the fans & peltier connect to the GND terminal of the W1209, and the GND wire from the PSU. When the W1209 turns on the system, it closes a relay that connects K1 to K0, and completes the circuit.

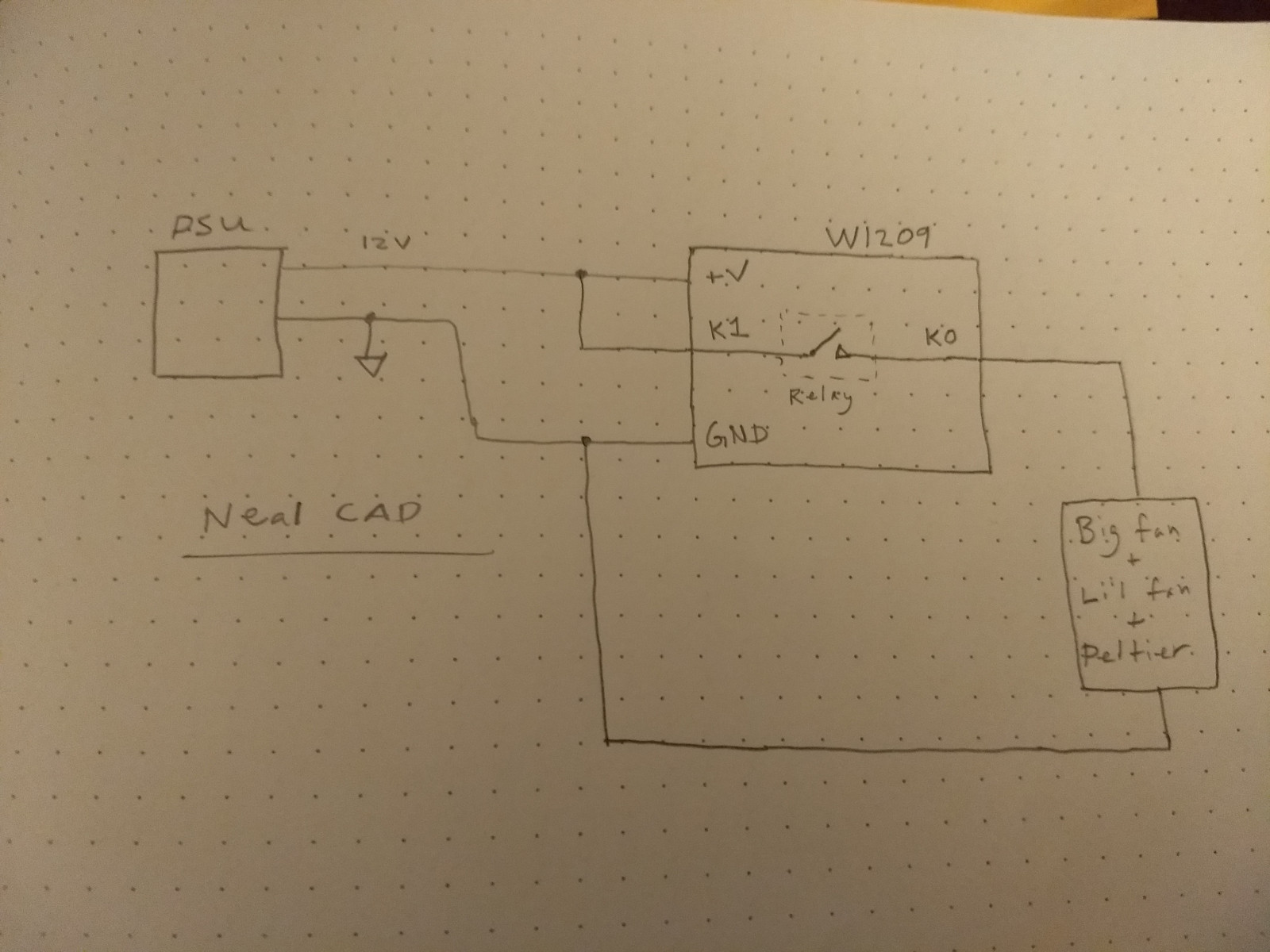

Here's a wiring diagram to illustrate:

Verifying that the system works is an important part of any project.

No problems there, so I moved on to installing the system in the cooler.

This part is easy, you just cut a hole in the lid of the cooler. I traced the perimeter of the coldblock heatsink, and used a drill to cut holes at each corner. I then used a knife to cut out the rest of the hole. I cut a chamfer around the inside of the hole, to improve air circulation around the heatsink.

To complete assembly, stick the coldblock in the hole, and place the thermal probe of the W1209 inside the cooler (location doesn't really matter, if you want to optimize it, then go for a location that provides consistent readings.)

Results

The machine works! After several hours in a room of about 70°F, it was able to reach 52°F. It very quickly begins cooling, and initially you can watch the temperature drop by about 0.2°F every five seconds. As time goes on, however, it takes longer and longer for the temperature to drop, and eventually it asymptotes. If you are making one of these yourself, expect it go to about a maximum of 20°F below ambient.

To recap, I started out with two simple design criteria:

- Keep things cool

- Not break the bank

I was able to reliably hit both these criteria, and had a good time doing it. If you're looking for a cool weekend project, give this one a shot.